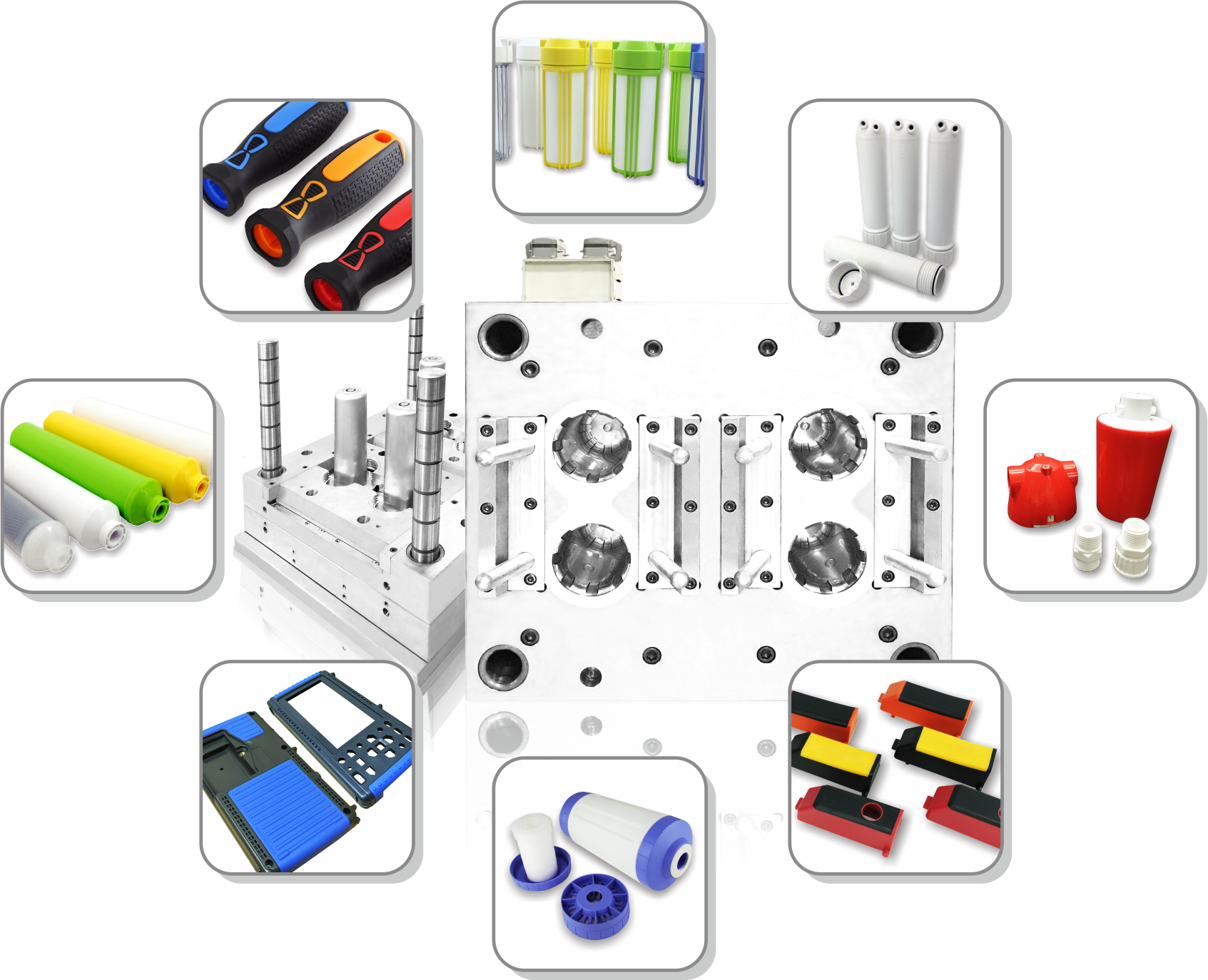

Plastic Injection OEM/ODM Service

Production information

Taiwan Custom ABS PVC PE PP PC PA Nylon plastic injection moulding service for plastic products

Mould Specification:

| Mould Base Material | LKM, HASCO , DME |

| Mould Cavity Material | P20, 718H, S136 , NAK80 ...etc. |

| Plastic Parts Material | ABS , PP...etc. |

| Cavity | Single or multiple cavities. |

| Runner | Hot & Cold Runner |

| Gate | Pin-Point Gate , Edge Gate |

| Design Software | CAD, UG...etc. |

| Main Processing Equipment | CNC , Cutting ,Carved , Milling, EDM...etc. |

| Surface Treatment | Electroplating , Screen Printing , Texture, Polishing...etc. |

Mould Package:

Wooden Case

Mould Process:

| 1 | Quotation | Need 3D Drawing or Samples provided by customers. |

| 2 | Mould Design | Mould Design will be provided for confirmantion 1 week after receiving down payment. |

| 3 | Mould Fabrication | Start mould fabrication right after the mould design is appoved by customers. |

| 4 | Mould Trial | 1st trial sample will be available for reviewing. |

| 5 | Sample Confirmation | Submit the trial sample to customers for checking and confirmation. |

| 6 | Mould Modification | Modify the mould if necessary according to customers' agreement. |

| 7 | Mould Delivery | Deliver the mould after receiving the balance payment. |

| 8 | Plastic Injection Service | We could keep the mould and provide plastic injection service if needed. |